Basic Info.

Model NO.

zjt panel-1001

Fire Rating

4

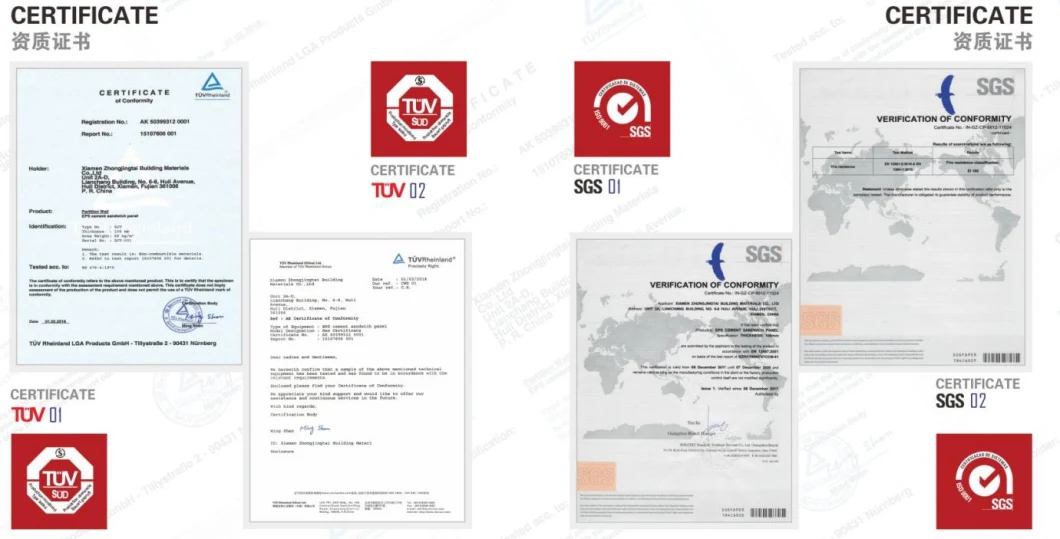

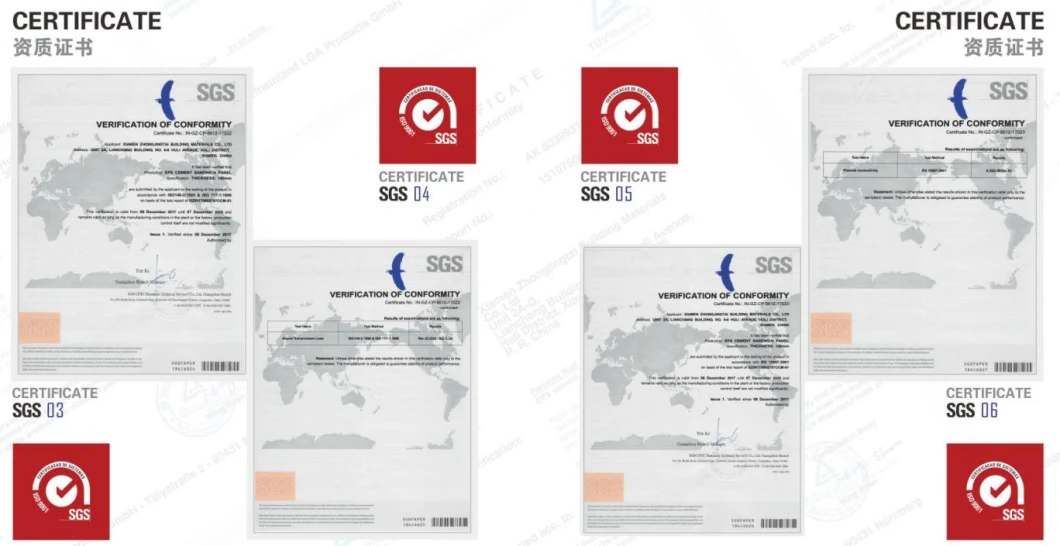

Certification

SGS, TUV

Customized

Non-Customized

Facing Panel

Fiber Cement Board/Calcium Silicate Board

Core Material

Cement, EPS and Sand, Fly Ash

Certificate

TUV, SGS

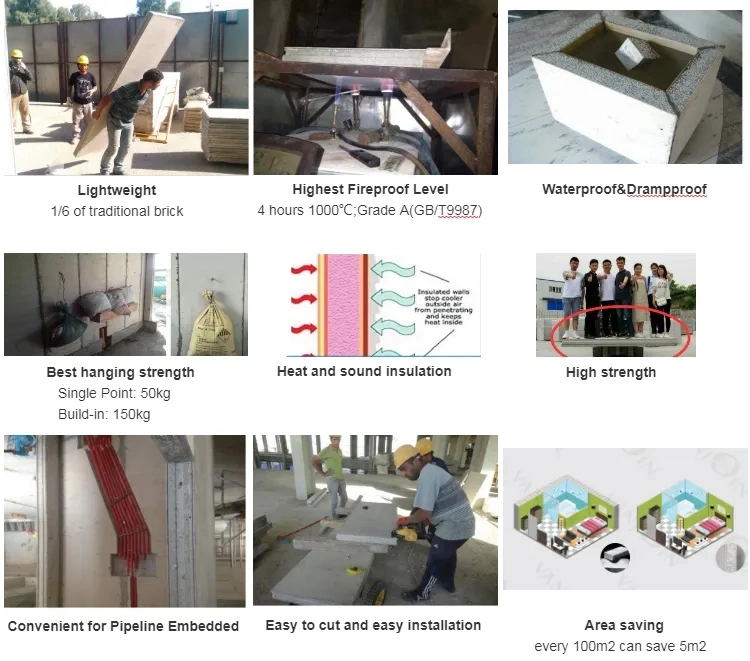

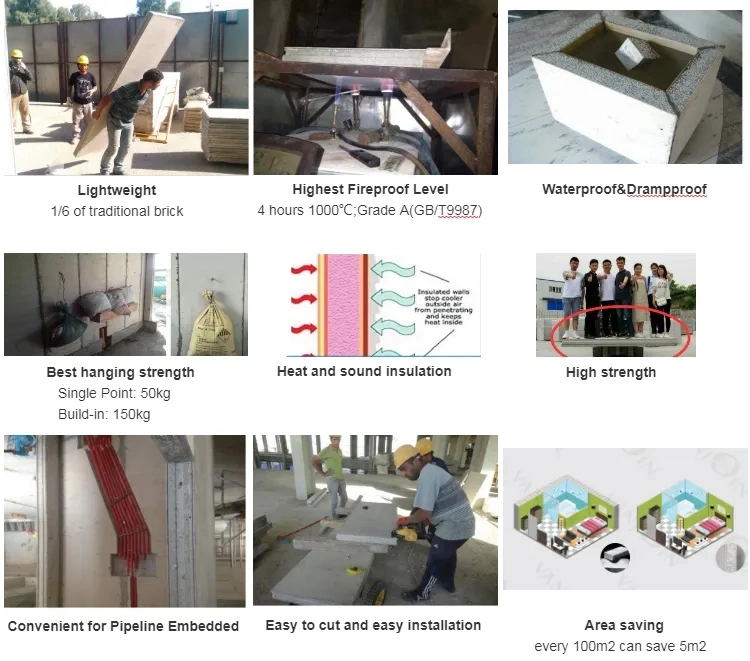

Light Weight

1 Person Can Take up Two Pieces

Application

Wall/Roof/Floor

Installation Speed

15sqm/Person/Day

Fireproof Limit

>3hours

Anti-Pressure

>3.5MPa

Hanging Force

1000n

Anti-Bending Damage

>3.5MPa

Bulk Density

550-650 Kg/M*2

Softening Coefficient

>0.8

Sound Insulation

42dB

Insulation Height

>10m

Moisture Rate

<10%

Transport Package

Pallet+Pearl Wool+Corner Paper+Belt+Plastic Film

Specification

60/75/90/100/120/150mm

Trademark

ZJT

Origin

Fujian, China

HS Code

6810999000

Production Capacity

10000 Sqm Per Month

Packaging & Delivery

Package Size

15.00cm * 20.00cm * 20.00cm

Package Gross Weight

2.000kg

Product Description

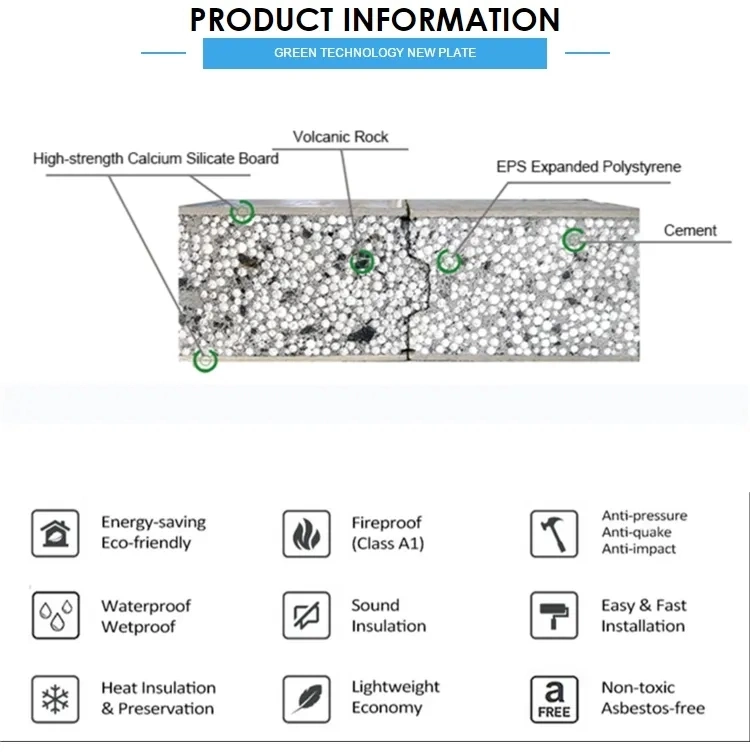

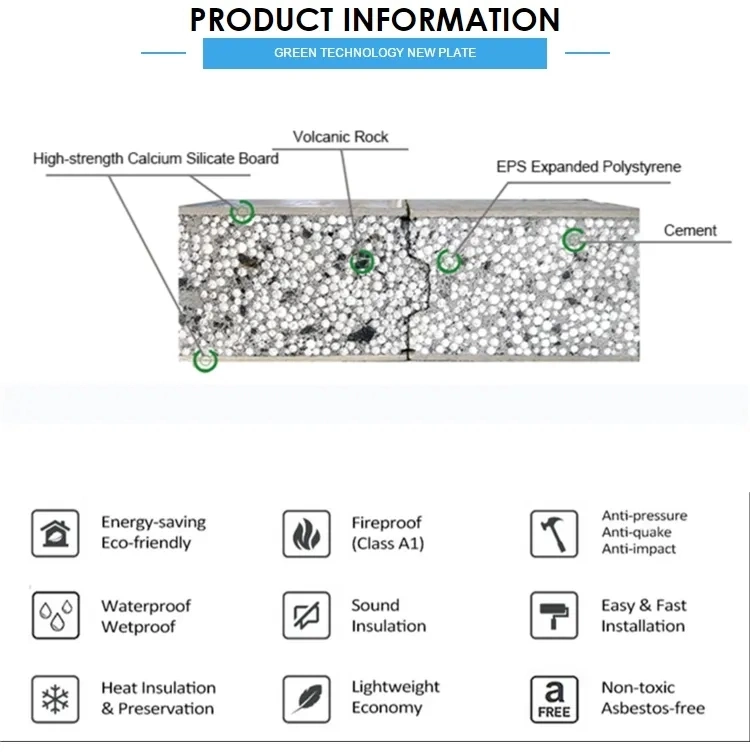

Product Information

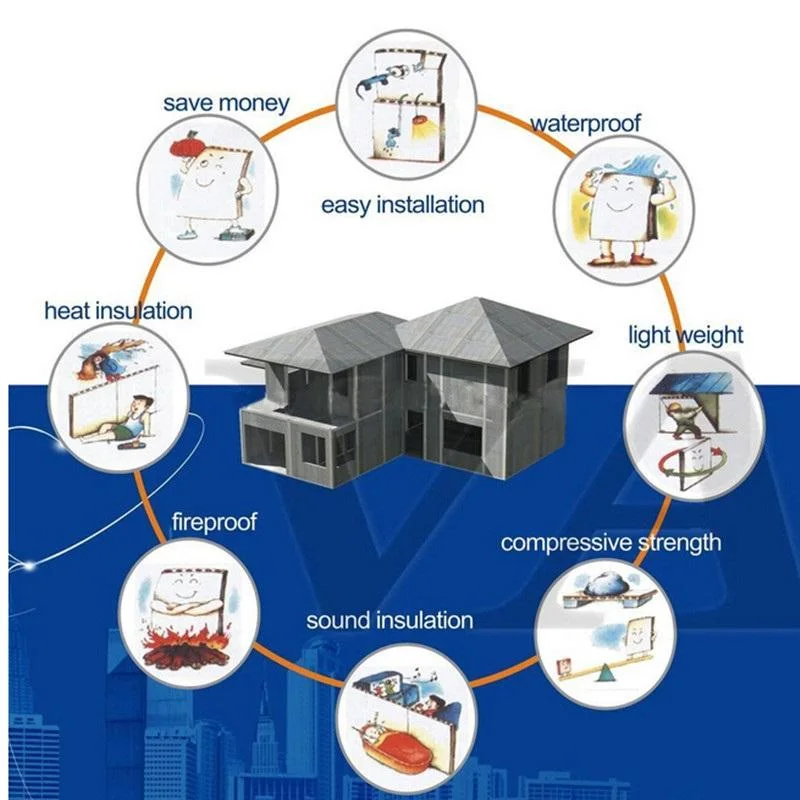

ZJT Light Composite Energy-saving Sandwich Wall Panel is composed of face panel and interior filling. The quality and technology of product have reached to a new level and become the leading brand among the similar products.

The product has solid,lightweight,thin,better strength,impact resistance,hanging strength,heat insulation,sound insulation,fireproof,waterproof,easy cutting,pet and rot resistant,increasing usable space. It can be arbitrary slot,without batch file,dry operation,enviroment protection,which achieve energy conservation and energy efficiency. At the same time,this reduces the total area to be occupied by the wall and to raise residential practical area,alleviates the structure load,improves the building aseismatic capacity and safety performance,and reduce total cost. This production technology and application is the reform of our country wall material,is a new breakthrough.

The company relying on advanced equipment,first-class technology,excellentquality,strong,productivity,favorable customer service system,has set up the good brand image in the market,and been widely recognized by the same.

Product Composition

Surface: fiber cement board

Interior filling materials: EPS , cement, fly ash , sand , additive

Product Advantages

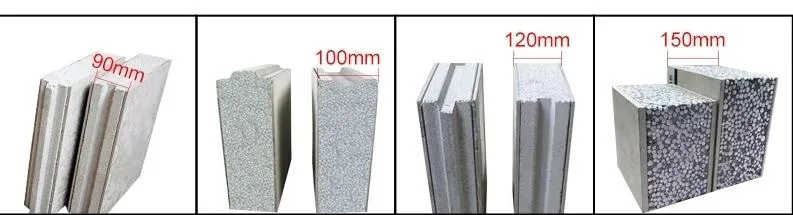

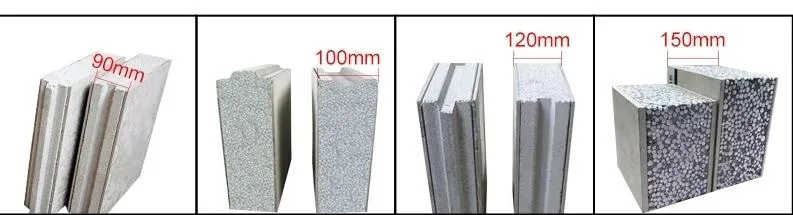

Product Size

Thickness: 60/75/90/100/120/150mm

Length: 2270/2440mm

Width: 610mm

*The sandwich panel size can be customized accroding to the needs of users' requirements

Technical Index

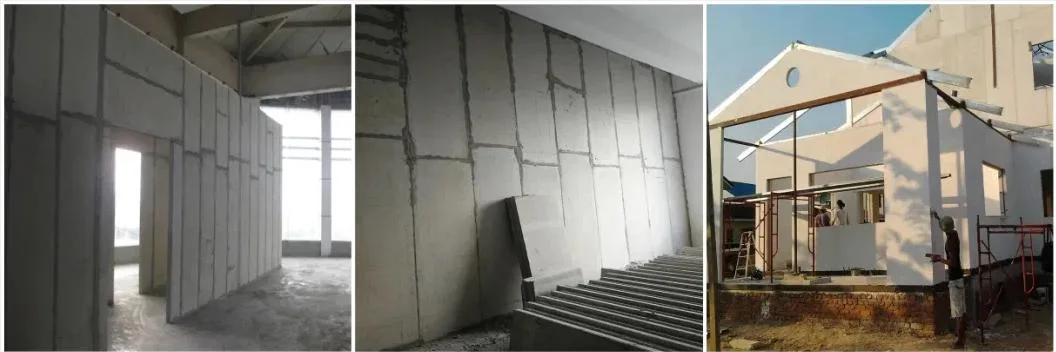

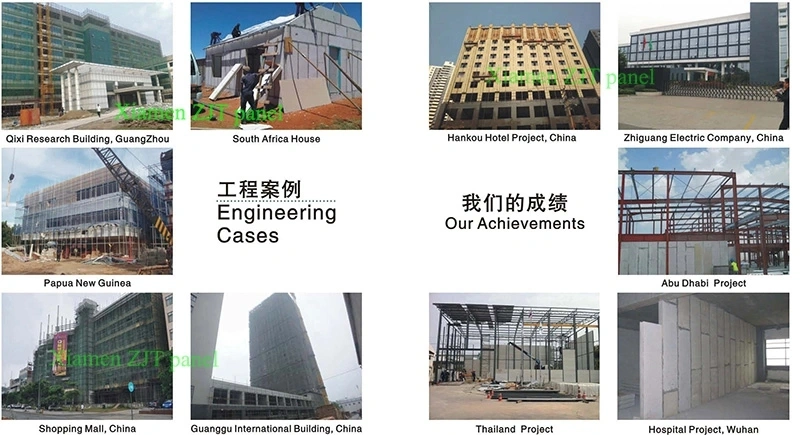

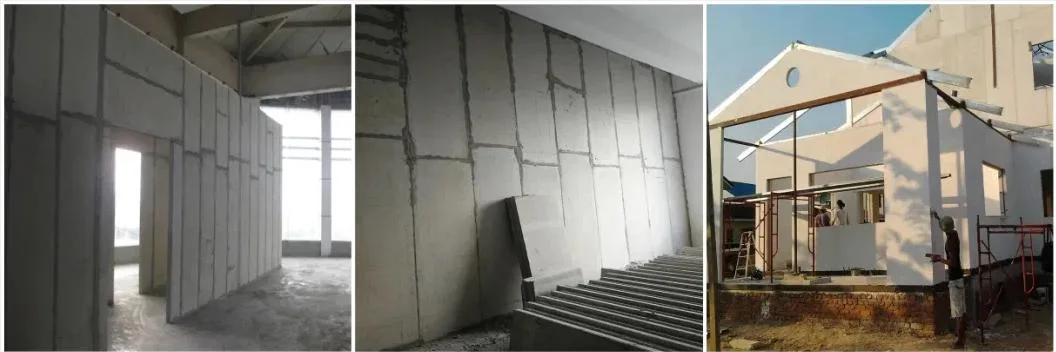

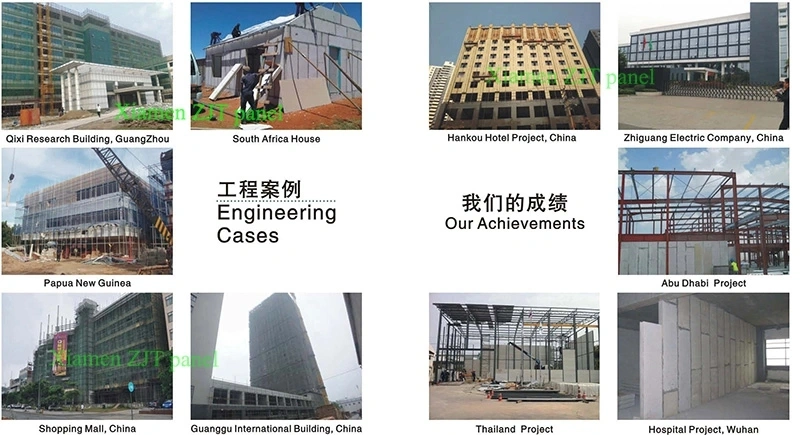

Product Application

widely used:

office,residential building,school,hospital,hotel,public construction,entertainment place.

wall/exterior wall/interior wall/super high wall/abnormity wall/roof/floor/prefab building/

pipe/fire well/equipment partiton

1).Interior partition (60/75/90mm is your best choice)

2).Exterior Wall (100/120/150mm for your reference)

3).Floor and roof

4).prefabricated houses

5).Modern high-rise Building

6).Schools, Hotels, office

7).Indoor space of ecological residences

8).All kinds of houses and structures

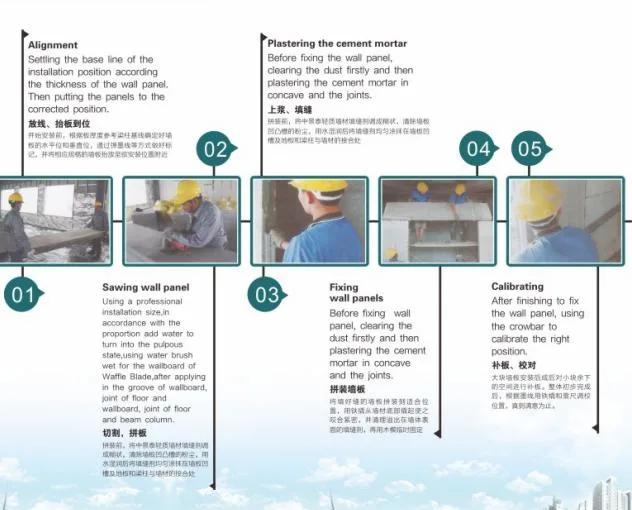

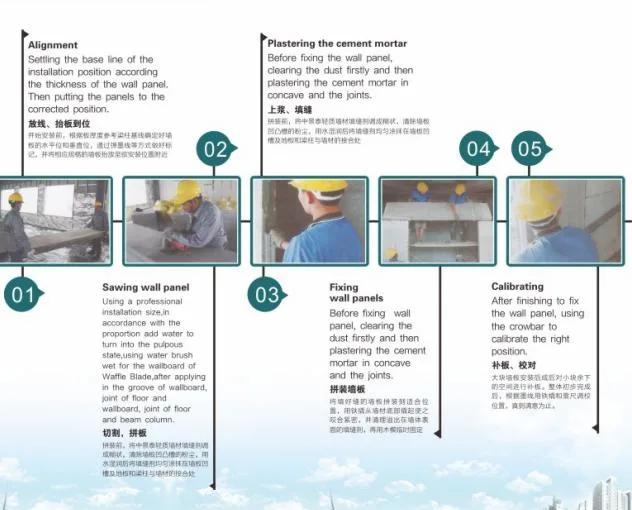

Installation Process

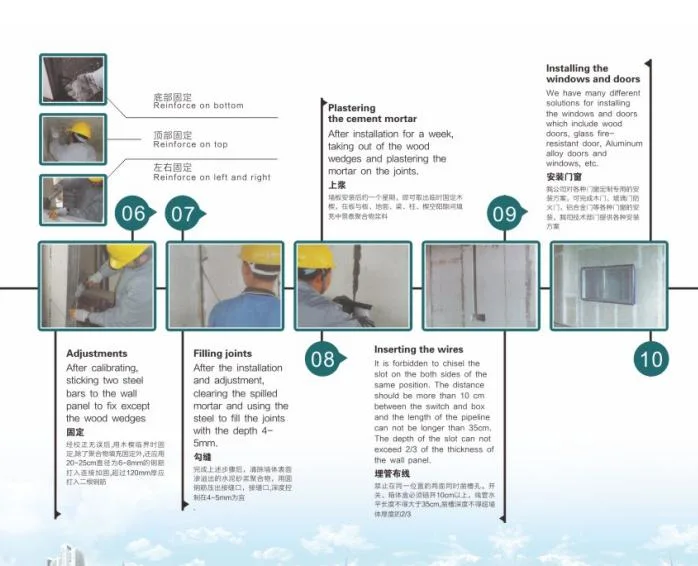

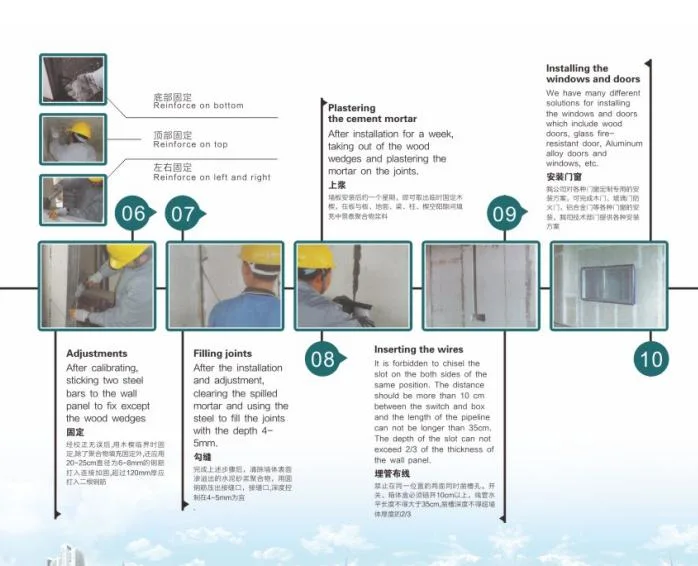

Notice: Adjustment have three steps. The first is reinforce on bottom . The second is reinforce on top . The third is reinforce on the left and right .

Certification

Packing & Delivery

1).Held by wooden Pallet or without Pallet;

2).Bonded with plastic belts;

3).Fasten around the corners;

Trade Terms

1).Payment: T/T or L/C at sight;

2).Lead time: 20-25 Working days;

3).Shipping freight are quoted under your requests;

4).Shipping port: Xiamen port, Mainland China;

5).Discount: based on the order quantity;

Company infomation

In the trend of low-carbon and energy-saving in domestic, ZJT is on a mission environmental protection, and actively promoting the development and popularization of green building materials. The composition of the materials of ZJT energy-saving wall panel strictly implements national GB6566-2001Building Materials Radionuclide Limited standard, which belong to the main of the radioactive building materials and a kind of decoration materials, 100% do not contain harmful substances in humans, and in high temperature combustion state, the release of excessive part also can be operated in an efficient range so it has no direct threat to human. At the same time, the construction of the product itself almost do not produce construction waste, in the demolition of buildings the product has the reuse rate of as high as 72%-93%, so these features make it surely become one of the most environmental protection administration of green environmental protection building materials.

Contact information

Allenby

Xiamen Zhongjingtai Building Materials Co.,Ltd

ZJT Light Composite Energy-saving Sandwich Wall Panel is composed of face panel and interior filling. The quality and technology of product have reached to a new level and become the leading brand among the similar products.

The product has solid,lightweight,thin,better strength,impact resistance,hanging strength,heat insulation,sound insulation,fireproof,waterproof,easy cutting,pet and rot resistant,increasing usable space. It can be arbitrary slot,without batch file,dry operation,enviroment protection,which achieve energy conservation and energy efficiency. At the same time,this reduces the total area to be occupied by the wall and to raise residential practical area,alleviates the structure load,improves the building aseismatic capacity and safety performance,and reduce total cost. This production technology and application is the reform of our country wall material,is a new breakthrough.

The company relying on advanced equipment,first-class technology,excellentquality,strong,productivity,favorable customer service system,has set up the good brand image in the market,and been widely recognized by the same.

Product Composition

Surface: fiber cement board

Interior filling materials: EPS , cement, fly ash , sand , additive

Product Advantages

Product Size

Thickness: 60/75/90/100/120/150mm

Length: 2270/2440mm

Width: 610mm

*The sandwich panel size can be customized accroding to the needs of users' requirements

Technical Index

| Item | Testing Indexes | |||||

| Thinkness[mm] | 60 | 75 | 90 | 120 | 150 | 180 |

| Anti-impact Capacity/Items [standard sandbags/times] | ≥5 | ≥5 | ≥5 | ≥5 | ≥5 | ≥5 |

| Anti-bending Damage Load [times over deadweight] | ≥3.0 | ≥3.0 | ≥3.0 | ≥5.0 | ≥5.0 | ≥7.0 |

| Compressive Stregth [Mpa] | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 |

| Softening Coefficient | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 |

| Surface Density [kg/m2] | ≤70 | ≤70 | ≤90 | ≤110 | ≤110 | ≤130 |

| Moisture Rate [%] | ≤10 | ≤10 | ≤10 | ≤8 | ≤8 | ≤8 |

| Drying Shrinkage Value [mm/m] | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| Hang Force [N] | ≥1000 | ≥1000 | ≥1000 | ≥1000 | ≥1000 | ≥1000 |

| Sound Insulation Capacity In The Air [dB] | ≥35 | ≥35 | ≥40 | ≥45 | ≥50 | ≥55 |

| Fire Endurance [H] | ≥1.5 | ≥1.5 | ≥2.5 | ≥3.0 | ≥4.5 | ≥6.5 |

| Heat Transfer Coefficient [W/m2.k] | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 |

| Inner Radiation Index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Outer Radiation Index | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

Product Application

widely used:

office,residential building,school,hospital,hotel,public construction,entertainment place.

wall/exterior wall/interior wall/super high wall/abnormity wall/roof/floor/prefab building/

pipe/fire well/equipment partiton

1).Interior partition (60/75/90mm is your best choice)

2).Exterior Wall (100/120/150mm for your reference)

3).Floor and roof

4).prefabricated houses

5).Modern high-rise Building

6).Schools, Hotels, office

7).Indoor space of ecological residences

8).All kinds of houses and structures

Installation Process

Step 1: Alignment

Step 2:Sawing wall panel

Step 3:Plastering the cement mortar

Step 4:Fixing wall panels

Step 5:Calibrating

Step 2:Sawing wall panel

Step 3:Plastering the cement mortar

Step 4:Fixing wall panels

Step 5:Calibrating

Step 6:Adjustments

Step 7:Filling joints

Step 8:Plastering the cement mortar

Step 9:Insterting the wires

Step10:Installing the windows and doors

Step 7:Filling joints

Step 8:Plastering the cement mortar

Step 9:Insterting the wires

Step10:Installing the windows and doors

Notice: Adjustment have three steps. The first is reinforce on bottom . The second is reinforce on top . The third is reinforce on the left and right .

Certification

Packing & Delivery

1).Held by wooden Pallet or without Pallet;

2).Bonded with plastic belts;

3).Fasten around the corners;

Trade Terms

1).Payment: T/T or L/C at sight;

2).Lead time: 20-25 Working days;

3).Shipping freight are quoted under your requests;

4).Shipping port: Xiamen port, Mainland China;

5).Discount: based on the order quantity;

Company infomation

In the trend of low-carbon and energy-saving in domestic, ZJT is on a mission environmental protection, and actively promoting the development and popularization of green building materials. The composition of the materials of ZJT energy-saving wall panel strictly implements national GB6566-2001Building Materials Radionuclide Limited standard, which belong to the main of the radioactive building materials and a kind of decoration materials, 100% do not contain harmful substances in humans, and in high temperature combustion state, the release of excessive part also can be operated in an efficient range so it has no direct threat to human. At the same time, the construction of the product itself almost do not produce construction waste, in the demolition of buildings the product has the reuse rate of as high as 72%-93%, so these features make it surely become one of the most environmental protection administration of green environmental protection building materials.

Contact information

Allenby

Xiamen Zhongjingtai Building Materials Co.,Ltd